This prototype was built for a local plastic injection-molding company, as a product test for a new item. This makeup box had been designed and drafted for final mold making, but prior to that expensive step, the development team wanted a physical model both for photography and proof-of-concept.

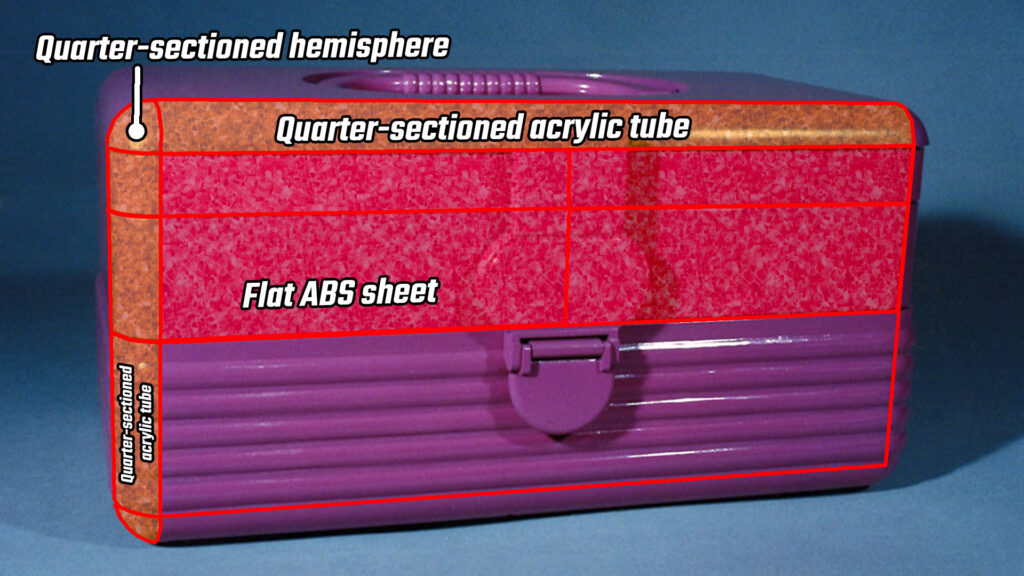

The box itself is constructed from 1/8″ thick precision milled ABS sheet, various acrylic tube sections, hemisphere sections, and acrylic mirror, then painted. The ribbed details running around the box and around the handle are thin urethane castings which were applied to the finish constructed box while still flexible, cured in place, then finished, sanded and painted.

Though much heavier than the production piece, all hinges, main latch, handle, and swinging trays were fully functional and sturdy. Dimensions and clearances involved were critical, and complicated by design elements such as draft angles, which needed to be compensated for.